Biological & Life Science

Manuscript Writing

- New Insights into Complex Role of Mitochondria in Parkinson’s disease

- Antibody Detection in Diagnosis of Schistosomiasis

- Effects of Biomass Particle Size in Cellulosic Biofuel Production

- Dissertation on Modelling Sugarcane Nitrogen Uptake Patterns

- An Integrative Review on Complementary and Alternative Medicine

- A Neuronal Trigger- Endoplasmic Reticulum Stress on Alzheimer’s Disease

Effects of Biomass Particle Size in Cellulosic Biofuel Production

Biofuels made from cellulosic biomass are one of the most promising near-term and mid-term replacements to petroleum-based liquid transportation fuels. Biomass size reduction is the first stage in the biochemical route for producing ethanol from cellulosic biomass, and it is generally done using a mill with a screen to regulate the size of the particles generated. The lack of comprehensive knowledge of the effects of screen size on the biochemical conversion of cellulosic biomass makes it difficult to select the screen size for biomass size reduction in order to reduce mill energy consumption, maximise cellulose recovery after pre-treatment, and maximise enzymatic hydrolysis efficiency.

Alternatives to petroleum-based liquid transportation fuels are becoming more and more necessary. Biofuels made from cellulosic biomass, such as specialised energy crops like big bluestem, forest leftovers, and agricultural residues, have been recognised as viable alternatives. Because of its low cost, availability, and sustainability, using cellulosic biomass as a feedstock for biofuel production is favourable.

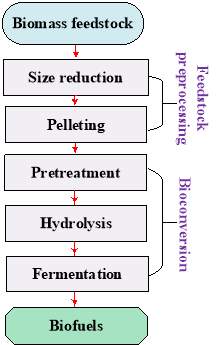

Size reduction, pelleting, pre-treatment, enzymatic hydrolysis, and fermentation are all important steps in the biochemical route for biofuel production. Many studies have found that the size of the biomass particle determines how much energy is used to reduce the size. Sugar yield in enzymatic hydrolysis is influenced by biomass particle size, and biofuel output in fermentation is roughly equal to sugar yield in enzymatic hydrolysis.

From a system engineering perspective, more quantitative process optimization is required to give practical recommendations on particle size selection. Trends must be confirmed on a large-scale platform. On the other hand, in future may focus on how mechanical effects during the feedstock pre-processing stage modify the compositional and structural characteristics of biomass, which influence biomass sensitivity to enzymes.