Applying Five Why Technique for Root Cause Analysis

Introduction

Any organization or process or team can be confronted with unanticipated challenges. Nonetheless, the challenges might just a symptom to an underlying issue. Prompt resolution of the challenge could prove to be the most feasible solution, but there is no guarantee that it might safeguard the organization or team or process from being confronted with recurring errors. Considering the scenario, it is important for the organization or the team in question to identify the root cause and tackle it in an appropriate manner. While there are several tools that can help an organization to conduct a root cause analysis, the ‘Five Whys’ technique is considered as one of the most effective tools in the repertoire of lean management. Teams are known to come face-to-face with roadblocks during their day-to-day work. Nonetheless, the use of five whys will enable the team to identify the root cause of any problem and thereby safeguard the process from such problems occurring in future, which might result in failure [1].

This blog aims to acclimatize you with the Five Whys technique for root cause analysis and inform you about how it can be effectively utilized to understand why a particular problem keeps occurring within your process. But first, it is important to trace the history of the Five Whys.

The Origins of Five Whys

Sakichi Toyoda was the person who has been attributed with developing the Five Whys. The idea behind developing the Five Whys was to spot the root cause to some problems that were being encountered at the manufacturing unit at Toyota. Over the years, the Five Why technique has been widely accepted and adapted by social scientists as well as educators to facilitate them to develop problem definitions and pertinent interventions [1]. The application of Five whys is quite simple wherein it comprises of converting a problem into a ‘why’ question. Five answers are brainstormed by participants on the basis of their experience and knowledge. Out of all the suggestions, the answer that is most feasible is chosen and converted into yet another ‘why’ question. This cycle is repeated five times. Participants are motivated to hypothesize and theorize on the problems in such a manner that it avoids assumptions that are unsubstantiated, sustaining relation to their lived experiences. Therefore, using the five whys technique requires careful facilitation on the part of individuals who are skilled in the practice of critical questioning and reflection and those who are well-versed in developing contexts which people are comfortable sharing [2].

Applying the Five Whys

At the time of applying the five whys technique, you might want to reach the essence of the problem and then try to find a solution. Sometimes, the five whys would reveal an unexpected source to the problem. More often than not, issues that are deemed as problems which would be technical nature would eventually reveal themselves to be process or human problems. That makes it necessary to apply the five whys to find and eliminate the root cause to restrict the scope for the same problem from recurring [3].

[Note: Searching for the Strategic Management dissertation writing help? Mail us to info@tutorsindia.com]

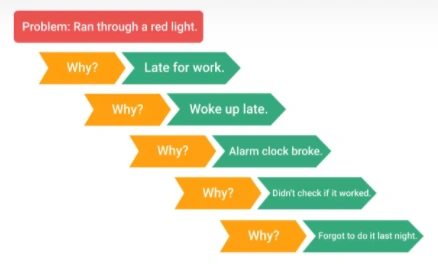

Figure 1: Five Whys in Action

Source: Serrat [3]

From the above example (Figure 1) the root cause for running through the red light turned out to be a simple overlooking of a task which could be attributed to a human error. But, this problem has scope to repeat itself if remedial steps are not initiated.

To conduct a root cause analysis using Five whys you need to;

Form a Team

Make a team comprising of an individual each from the department that is being impacted by a recurrent problem. Or in case of an individual, seek the help of family members or friends to form a core team. In either case, all the individuals within the team should be aware of the problem that is going to be investigated. Team formation will allow you to arrive at an informed decision [4].

Define the Problem

At the outset, you should deliberate the problem with your team members and construct a clear problem statement. It would be helpful in outlining the scope of the problem that will be investigated. This is significant as exploring a problem with a wider scope might be process which is time-consuming and the boundaries too might be blurred. Remaining focused throughout would help you to reach an effective solution [5].

Ask Why

One person from the team should be empowered to be able to facilitate the entire procedure. The questions will be asked by the team leader and he or she would also attempt to ensure that the team remains focused throughout. Care should be taken to ensure that the answers to each why is based on real data and actual facts rather than getting carried away by emotions [4].

Take Action

Once the root cause has been identified by the team, they should then focus on initiating corrective measures. Each member should participate in a discussion to seek and apply the most appropriate solution that will safeguard the process from the same problem recurring again. Following a specific period of time, the team should meet again to understand whether the solution they found made a positive impact. In case it is not making a positive impact, it would be necessary to repeat the process [5].

Conclusion

The Five Whys has been proven to be a very robust and potent organizational technique to identify root cause. Using five whys can add agility to your team and also presents your organization with the grounds to promptly respond to problems as it might emerge, without the need for any over-engineering or overinvesting.

References

[1] S. Moaveni and K. Chou, “Using the Five Whys Methods in the Classroom: How to Turn Students into Problem Solvers,” J. STEM Educ., vol. 17, no. 4, 2017, [Online]. Available: https://www.learntechlib.org/p/174416/.

[2] D. Kohfeldt and R. D. Langhout, “The Five Whys Method: A Tool for Developing Problem Definitions in Collaboration with Children,” J. Community Appl. Soc. Psychol., vol. 22, no. 4, pp. 316–329, Jul. 2012, doi: 10.1002/casp.1114.

[3] O. Serrat, “The Five Whys Technique,” in Knowledge Solutions, Singapore: Springer Singapore, 2017, pp. 307–310.

[4] F. M. S. Al-Zwainy, I. A. Mohammed, and I. F. Varouqa, “Diagnosing the Causes of Failure in the Construction Sector Using Root Cause Analysis Technique,” J. Eng., vol. 2018, pp. 1–12, Oct. 2018, doi: 10.1155/2018/1804053.

[5] F. M. S. Al-Zwainy and R. A. Mezher, “Diagnose the causes of cost deviation in highway construction projects by using root cause analysis techniques,” Arab. J. Sci. Eng., vol. 43, no. 4, pp. 2001–2012, 2018, [Online]. Available: https://link.springer.com/article/10.1007/s13369-017-2850-2.