The US and the UK Master’s Part / Chapter-wise Dissertation Writing Service

Then You’ve Certainly Reached the Right place

Assignment On Mechanics and Properties of Materials

Properties of Titanium Alloys

Introduction

As the engineering field has been existent from time immemorial, Titanium and its alloys can be considered as new entries in the ever expanding list of elements that are millions of year’s old. They are widely used only since 1950s. It is found in some of the South American, African, Asian and European countries with Australia topping the list. Titanium and its alloys are the preferred choice in many of the engineering applications due to their resistance to corrosion and hence used extensively in marine applications. Its other advantageous properties are its strength and its tolerance to high temperature.

As it is not a freely occurring element it occurs in combination with minerals like perovskite (calcium titanate), rutile, arizonite (iron titanate), brookite etc. the properties of pure titanium can be summarized as follows:

- Density-4540 kg/m3

- Stretchability -110 x 109 Pa.

- Melting point -1668oC

According to the presence of impurity in the metal, titanium is graded as between grade 1 to 4. 4 th grade titanium is considered as pure titanium. The alloys of titaniumTitanium alloys finds place in a variety of applications and they are divided into three groups as:

- Alpha alloys: used in aircraft applications.

- Beta alloys: used for weighty tasks in airliners

- Alpha-Beta alloys: used in sea water applications

Manufacturing process - Kroll’s process:

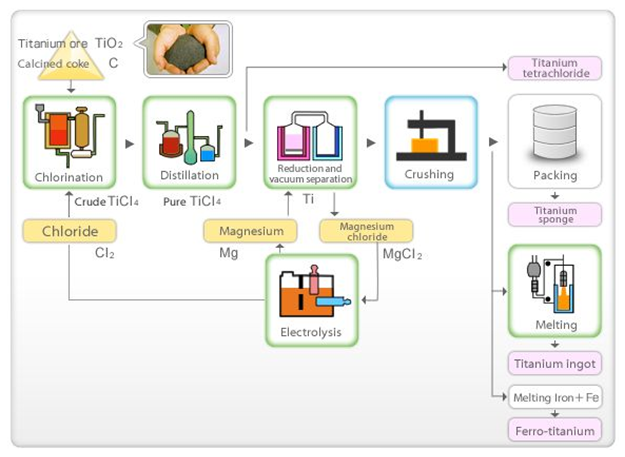

One of the mineral constituent of titanium called termed rutile and the oxide of titanium termedcalled titanium oxide are the raw materials involved in the production of titanium. The initial step involves the production of titanium chloride by the chlorination and subsequent distillation processes. Then by treating the TiCl4 with magnesium, titanium is produced. The sequential steps are summarized below:

Treatment with chlorine:

Titanium oxide at temperatures as high as 1000 degrees, releases oxygen and forms a tetrachloride with chlorine called titanium tetrachloride. This reaction takes place in the presence of coke which acts as a reducing agent.

TiO2+ C+ 2Cl2= TiCl4+ CO2

Subsequent distillation to obtain TiCl4

A sponge of titanium is then generated by treating the titanium chloride with magnesium metal at a temperature of about 9000 C. by this reaction, titanium is separated and the released. Magnesium chloride is removed at regular time gaps by extracting in a vacuumed atmosphere. The resulting product is called titanium sponge

TiCl4 + 2Mg= Ti +2MgCl2

Treating in the presence of a reducing atmosphere or Vacuum will remove the magnesium

The process of electrolysis:

The magnesium chloride thus obtained is then decomposed into magnesium and chloride. Thus magnesium and chlorine are recycled for further use.

MgCl2 = Mg 2+ + 2Cl-

Crushing, molding into proper size and packing:

By crushing, shearing and blending of the obtained sponge, the titanium is made into particles of the required size.

Researchers to mentor-We write your Assignments & Dissertation

With our team of researchers & Statisticians - Tutors India guarantees your grade & acceptance!

About serviceMelting the product

It is in this process that the required titanium alloy is made by mixing the alloying elements to the sponge of titanium. This is done in the absence of other elements that could easily react with titanium.

The process of feeding titanium chloride-TiCl4 and the rapidity of removing the heat generated are two important processes that influence the yield of titanium.

Here the required alloy is introduced and the product is obtained. Titanium alloy that has high quality elasticity and working efficiency is the one which contains by mass %, 0 of 0.2% or less, Fe of 0.15 to 3.0%, and Mo of 0.85 to 3.15%, V of 3.5 to 4.5%, Al of 5.5 to 6.5%, Cr of 0.15 to 3.0% Mo, Fe, Cr and are already standardized. With a high content of aluminum, this alloy is highly resistant to cold and extremes of temperature.

Material property requirements

Ti-6Al-4v: it is evident from the experiments that the property of titanium -the “centralized shearing slipping” through the mechanism of “cutting deformation” is the major property offering improved efficiency at milling for the alloy

Addition of aluminium and molybdenum to titanium can be done in order to improve the strength and its tolerance to corrosion. If zirconium is further added to the alloys it would result in the further improvement of the properties that offer resistance to corrosion.

An alloy of Titanium with a combination of Ti-Mo with Mo contributing to 0.2 to 3.0 wt % is useful in providing corrosion resistance. However the majority of components in the alloy is titanium and also the maximum amount of iron Fimpurities should be less than 0.1%. the availability of oxygen should be in the permitted standard as per the equation: Mo (%). O2 (%)≤9/35-1/28Mo (%)

Another alloy that is worth mentioning is the said titanium alloy. It is well known for its virtue of being the corrosion resistant compound and can withstand corrosion even in the presence of bromide ions. It is also of high quality in formability. It can withstand heating temperatures upto and even more than 700° C. At particular permitted and standardized conditions, it is malleable.

Advantages of Titanium Alloys

- A notable advantage of titanium alloys is particular resistance to decomposition even in the presence of oxygen and chlorine. It is flexible as it can be made both supple and sturdy according to the type of application.

- The tolerance of titanium alloys to extreme heat also highlights it as the preferred material in many fields

- Due to the properties of titanium alloys like strength, ability to strip roll, and significant formability they are extensively used in the aircraft industry.

- The beta titanium alloys like “Ti-13V-11Cr-3Mo, Ti-15V-3Cr-3Al-3Sn, Ti-6Al-4V, and Ti-3Al-8V-6Cr-4Mo-4Zr” and other alloys have contributed significantly in the development of aircrafts like SR-71 Blackbird, the Boeing 777, B-1B bomber etc.

- An Alpha-Beta alloy of titanium that comprises of aluminum and vanadium is used in the aircraft manufacturing, applications in the sports arena etc. This is due to its extreme strength and tolerance to corrosion

- Titanium combined with palladium along with oxygen is used extensively in chemical industries

Disadvantages

- It is a costly metal and it is even more costly to mould it and to extract it by Kroll’s process.

Full Fledged Academic Writing & Editing services

Original and high-standard Content

Plagiarism free document

Fully referenced with high quality peer reviewed journals & textbooks

On-time delivery

Unlimited Revisions

On call /in-person brainstorming session

More From TutorsIndia

Coursework Index Dissertation Index Dissertation Proposal Research Methodologies Literature Review Manuscript DevelopmentREQUEST REMOVAL