Engineering & Technology

PHD Dissertation

- Architecture Robots & 3D Printers

- Downsizing and Turbocharging

- Advanced Combustion Modes

- Organ-on-a-chip

- Water minimization techniques

- Virtual Realities and Immersive Architecture

- Technological Developments For Electrical Vechicles

- Drones or Unmanned Aerial Vehicles(UAVs)

- Modular Construction and 3D Printed Dwellings

- Advances in Gas turbine technology

Advances in Gas turbine technology

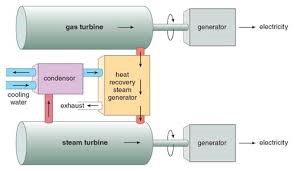

Gas Turbines have become an integral part of modern life. They are utilized in the field of power generation, shipping and air transport. From being a condensed way of distributing power, Gas Turbines have evolved into marvels of engineering due to advanced metallurgy, computational fluid dynamics, and additive technology among others. Gas Turbines are simple machines with a compressor, to compress the working medium, a combustor, to radiate heat into the working medium and a turbine, to convert the heat energy as to drive the compressor and produce useful work[1]. Therefore, the performance of the gas turbine hinges on on the effectiveness of the individual components and their performance. The advances in Gas Turbine Technology are as follows:

- Computational Fluid Dynamics in Compressor Design: 3D design modeling uses advanced software to increase the pressure ratios up to 30:1. The Compressor efficiency is enhanced using the three-dimensional computational fluid dynamic codes.

- Increasing Turbine Inlet Temperature: Engineers across the world use thermal barrier coating, blade cooling techniques, single crystal blades and additive manufacturing to improve the efficiency of turbine blades[1].

- Blade Cooling Technology: There are many techniques of cooling used in gas turbine blades such as convection cooling, and effusion cooling which remove heat from the turbine blades.

- Jet Impingement Cooling: It is very effective to impinge on the hot region.

- Thermal Barrier Coating: These insulate components from prolonged heat loads.

Fig 5: Gas Turbines

These advances in technology will enable constructing a Gas Turbine with much higher capacity that occupies less space.